In the beginning...

This was the discovery of the deck roll and the start of a dream.

In 2014, while Kevin and I were designing the YETI SnowMX kit, we spent as much time as we could riding in the mountains. However, loading and unloading our bikes was always a hassle, whether we used the back of a truck, a traditional sled deck, or a trailer.

In 2015, we decided to take one of our old trucks—a 2007 GMC ¾ ton SL model with 165,000 km—outfitted it with new wheels, tires, a 4” lift kit, and a roofrack. We brought it to Serge in Sicamous, BC, who had a winch deck on his truck and always raved about how easy it made loading and unloading. After a month with Serge, our truck was finally equipped with a simple winch deck, and for the first time in two years, the process was becoming easier.

July ride: fun & failures

My son wanted to go ride in them month of July for the first time, so Kevin figured we could get up to a place so on July the 4th we went riding in the new truck and it was great to use the deck, it made loading and unloading much easier, especially on uneven ground or slush or ruts or whatever, wherever we went.

We did ride a lot of gravel to get to the snow, but in the end it was a great trip on a warm day!

You can see the deck there for the first time with the fold up and down sides. It slid on a angle iron base with some plastic it was simple and effective.

However, it did not take long to break it, Kevin is known to be hard on equipment and I think we broke the cable on the winch in the first week from our own neglect hanging it up on the edge as we loaded it. Regardless we enjoyed using this deck!

The most fun was watching Kevin back up the truck at speed and slam the brakes on to get the deck to unload, that was always entertaining!! I wish I had a video to share on that step, but it always got a ton of attention if we were in a busy parking lot. I am sure people thought he was crazy, backing up at 30mph then slamming on the brakes to get the deck to move back if it was stuck.

2018: Chev Deck redesign

Back at the shop I was thinking on some new ideas…

In 2018 after two years of using the “YETI truck”…. (we started to call it) we were always thinking of how we could improve it as we broke it and repaired it time and time again. We broke the frame on the mount, the rear roller, the springs, the cable, multiple welds, the frame, the mounts etc., and we switched winch cables multiple times etc…it was common to be ready for the cable to snap and re-tie it right on the spot.

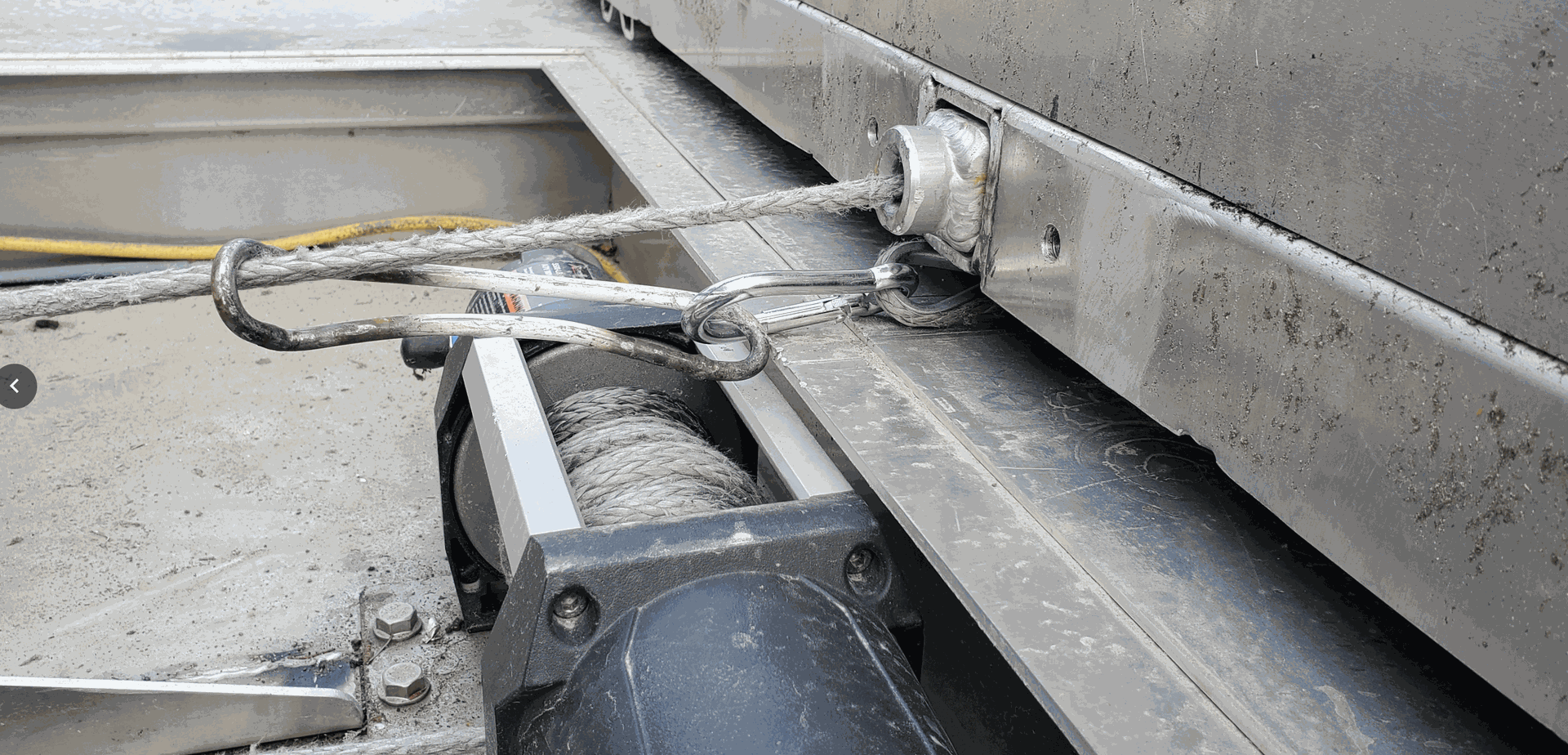

The winch cable had multiple knots at the end where it attached and Kevin got really good at swapping it out all the time and re tying it back to the deck while it was loaded, in the mud, in the snow or whatever it was.

It was always a bit scary when it snapped and dropped to the ground, loaded with bikes.

So Jamie got a chance to buy a 2001 Chev ¾ ton truck from one of our YETI SnowMX dealers and I dropped it off with Brewster West Motorsports to have Cory Brewster make the deck that came with the truck a movable deck, hoping to improve what we were already using.

This is how it looked when we started a with a fixed deck on the truck.

In the end it did not look any different, just that the deck would come off it.

However we did not use the truck too much as Jamie used a trailer mainly as he had to drive from Edmonton to BC to ride most times and liked to keep his bikes in the trailer, spring riding was done from the shop in Salmon Arm and we would just use the YETI truck.

3 years of deck trials

Kevin used the truck a lot in the next 3 winters always thinking of how we could improve it as we broke it and repaired it time and time again. We broke the frame on the mount, the rear roller, the springs, the cable, switched cables multiple times etc…it was common to be ready for the cable to snap and re-tie it right on the spot.

The deck had been fully re-welded and rebuilt a couple of times, however it was really starting to fail and keeping up with it and explaining the idiosyncrasies to each person that borrowed the truck was getting to be a hassle.

Regardless of the deck breaking we loved it and kept dreaming of how we could build our own and make it a great product for all in the future.

We used the truck to haul bikes, YETI SnowMX kits and parts between Edmonton and Salmon Arm BC, many many times

In the mean time Kevin used the deck for many purposes around home and the shop and fell in love with the utility aspect of the deck to help do many tasks easily.

And Jamie was using his and modifying that deck also for different purposes.

Note that the drivers side of the deck broke off, however we kept on using it. It was now 2019, 3 years of using the deck and dreaming of what could be.

2020: Hydraulic prototype

In 2020 we had a good customer who knows his stuff show up and ask if we could build him a hydraulic version of a deck he stopped by and met Kevin who looked it over in detail.

It had many great options, however it was really heavy duty and we thought that it was cool, however the price point would be much higher and that it would be too heavy for most trucks and the hydraulics made it more complicated.

We went riding again and thought about all this stuff. And one of our friends showed us his new deck and followed us up to go ride also. However again loading and unloading required a ramp with his new bed. He had a custom ramp fabricated up to make it work.

However we did decide to build a hydraulic deck also to see what that might be like which lead to three versions of the hydraulic deck too.

From ideas to innovation

So in 2021 Kevin started to draw up design ideas and sketches…

We had now talked between the group of us that ride a lot together about how we could get the deck off the truck, this conversation would spark up now and then over a 4 year period. Once and a while Derek and Jamie would get Kevin on the phone and shoot ideas which always looking for another answer, we knew there was a way!

However it was Kerry Cooper who came up with an idea to use a recoil rope like on a sled… We loved using the deck so much we knew we had to make it better and simpler.

We had ideas of electric motors, chain drive with gears at the rear, springs, more springs, cable pull etc… one way bearings, driven live roll, clutch etc…on and on

We also had some friends inspire us on as their vehicle loading and unloading techniques had some room for improvement, they thought. One other thing to consider is where do you stand when you are going to put your riding gear on? Especially when it is muddy? Think about that….

I think these guys thought about that, especially after walking the “tongue” lol!

That video was so much fun here is another! This was good motivation to have a Recoil deck!! lol

And so the drawings started, Kevin got the ball rolling.. It began with the hydraulic idea and sketches of tail lights, we wanted it to look appealing.

then more and more drawings and away we went…

but the riding and ideas never stopped, the sounding board just got larger and more ideas came in.

Hydraulic deck evolution

Then the Hydraulic deck build started.

We had to run it with the crane to see how it moved and looked, fun!

Then we decided to build a Defender deck for an experiment in March 2021

The defender was fun, we even used it to rescue Jamie’s son’s sled when the stator blew back in the mountains of Blue River.

And of course Jamie had to use

it to take his bike to the top of the mountain one time. It also

had a tilt deck and winch release on it with the wheels, we were

learning new things.

And then we finished the first hydraulic deck. Might as well keep learning and building.

We did like this unit and I used it for a few winters but overall it was more expensive and complicated that we thought it needed to be.

We kept pushing ahead..

Old Deck, New Lessons

Kevin kept using the old deck none stop and it continued to inspire him to push ahead to build a reliable deck that everyone could use.

It was so handy for multiple things around the house, shop and yard, that he used it for everything that he could.

Of course we knew that the UTV market was also a target market and we used the ole deck to haul those also.

Note at this time, we did not have the Recoil system pulling the deck off. You had to use the brakes to get the load to slide, if the rope was slack it could be a quick unload. We knew we had to make it better, however we learned a lot!

And Kevin being Kevin, kept on using the old deck and breaking stuff, here he is about to slide off the side of the logging road. The YETI truck never stopped going for years as we kept on dreaming and building the new deck in our minds.

Hydraulic deck 2.0

So we started again, from scratch and worked on a new design. We wanted it to be stronger and we worked on the geometry and designed some new hydraulic rams.

And we also started to build an in the box Hydraulic one about the same time.

As much as we liked the Hydraulic deck and we had custom rams made at a later date we still preferred the simplicity of the winch deck. However we had not figured a good way to remove the deck easily. We started on shapes and custom design extrusion ideas. We really liked the strength and simplicity of the airliner track.

The birth of Recoil deck

There is always a better mousetrap!

Then we started on custom shapes to make the deck strong.

Kevin started to work on the height of the deck off of the truck frame and he printed many shapes to figure out what the idea shape might be. Then Kevin started to draw the deck and right from the start the idea of removable wheels came in.

Then the first prototype started to come together in our bay behind the C3 shop. This one was all bent sheet metal.

The new deck was done, Recoil deck #1.

Video of it working with the new Recoil roller design.

Then we armguard coated it.

Then Kevin went riding with the team

Then we started to cast the Recoil spring parts and

test.

Then we started on the toolbox design for the lower valence.

Then we started to overload it

and make it fail through usage

Recoil Deck v2

Then we made a second one - Recoil Deck version #2 and

put it on a Dodge dually for a friend.

he wanted a wood deck which was cool, it gave us ideas

We had a good idea that the deck was getting dialed in and a vision to make it very strong and lightweight with custom extrusions. The vision for that was solid. Now it was time to make the deck come off the truck easily. So in 2021 we built the start of the new Recoil deck, although we did not have a name for it yet.

We had shared ideas for 3-4 years with our key guys off and on every trip thinking on how we could do that part. Many times in the spring you are backing up a logging road and need the deck to be able to go up hill to unload, that would take some force. We discussed using gear drives and slotted decks that the gears would bite into, 12v linear actuators, electric motors on and on.

Kevin had an idea, and it would take some thoughts and many prototype parts. He had to make it so it when the deck comes over the top, it did not pinch the cable or nylon rope and the Recoil had to disconnect automatically each time you took the deck off and there had to be enough force to pull it off. After many prototypes Kevin got it. Here are a few pics showing the evolution to what has become our filed patent pending design.

Generation 1 of the latch and catch...

Crafting the

perfect build

Kevin started to work on custom wound springs for the Recoil system.

Here is a video showing how the initial ones started to work.

3D printed holder…design was evolving.

Video of recoil deck loading and unloading.

Then more shapes started to

come for extrusions.

Now time to integrate tool boxes.

Then the start of the rear apron and tail lights

Then the choosing of deck materials, thicknesses etc. Needed to have a plan before we started to do custom extrusions.

Then fenders

Then we started to cut them from scratch and build more to test.

Fit, Finish, and Function

We developed more ideas for helping the deck clear the hitch and operate smoothly.

video Kevin loading lawnmower.

I thought Kevin should start a lawnmower collection.

There is nothing easy about moving a hot tub, but this deck makes it easy!

But he kept on using it and learning non stop. It became an essential item to have on his truck for a small acreage, the uses never stopped. Dream extrusion shapes coming together. We found that it took a lot of time to form all the channels and then weld them all out and keep everything square, this led to many new extrusion ideas.

We wanted everything to fit together with a great fit and finish and then started to design how all parts will meet.

Then of course the deck needed to extend and haul longer snowmobiles, snow bikes and other items, so the next step evolved, the deck extension.

The hauling of stuff continues…

we played with tail light design and choices.

By now the process was working very good.

Recoil’s Next Chapter

It was time to take it a step further in design with Stainless cast parts and injection molded ideas, and a 5th wheel hitch mount. So, we designed our own hitch, had it tested in the USA and over a 18 month period and CastHaul was born, a mini 5th wheel hitch.

cast

parts started to complete

Video of the rear latch,

Meanwhile, we kept testing the old unit day after day, non-stop it has been used for 3 years now.

We got Shady a tent to work under as he continued to design and fabricate and evolve all ideas with Kevin.

Then Milron started to fabricate decks to test.

More final ideas for extrusions were starting to form. We wanted to make the best deck we could that was strong and light. So Kevin kept on designing.

the

3d printed parts never stopped coming

more

failures and more learnings all the way...

More CAD design...

The

logo was born, “Recoil”

Recoil x Shady's truck

The next version was taking shape of the Recoil deck. This version had most of the final parts in it, however we still had tweaks to do and things to improve as we learned more and more.

But the parts were fitting nice! We were really excited each time we got to put a new part on and test it.

Well it was time to assemble one more prototype on Shady’s 6’6” GMC truck. The learnings continued, however that deck has been great and has a couple years of non stop use on it now. It has been on since the spring of 2023.

Shady

made a jig and machined the Recoil deck spring castings to our

new spec.

we kept him busy. lol

video of Shady’ new Recoil deck.

Shady put it to the test right away!

Shady and Brian discussing the rear apron and tool box design for his truck.

Ellery putting on the

finishing touches on the new parts.

Shady tool boxes and apron complete

Custom extrusions starting to complete.

Shadys truck is complete.

Shady testing the extensions and design. More 3D printed parts to figure this out.

RECOIL deck Generation 1 and Generation 2 side by side pics.

Recoil Deck’s Grand Finale

Well after many years of building decks, we got to the 4th version of the Recoil deck in Summer of 2024. 3 Hydraulic decks, 1 UTV deck, The “OG” original winch deck, Jamie’s winch deck and 4 Recoil decks later we are on the last prototype deck of fitment and tiny details. It was time to take Jamie’s winch deck off and sell it to his buddie Sean. Then to install the 4th version and final prototype of the Recoil deck! The new machined rear rub bumpers had been completed.

The new deck was coated at Milron

It was set in place

New 5th wheel hitch mount

storage

box with 5th wheel inside

Of course Kevin gave it the lawnmower test!

That is the final prototype.

The next truck we built is the 2017 Duramax that we will be taking to the Hay Days September 7/8th show!

We are very excited to show our final product there to the public. We have trucks to install back at the shop but it is time to release the final product to everyone.

In-Box Deck: A New Era

After using the box off design, we started to develop an in the box unit. We have many friends who ride and have a mid-sized truck and or a super short box Ford or GM and we wanted to help the guy who rides with one sled or 1, 2 or 3 bikes out of his truck box. So the in box design was born.

video of in box design start.

Of course Kevin put one in his truck and went out riding with the crew

the inbox design was born and

working. We kept using it, in different trucks, learning each

day...

Then extensions were added to the in box deck.